Anton, my Dutch friend, had a study mission group of Healthcare MBA students from the University of Amsterdam visiting Seattle last week.

Friday morning I spent about four hours with them going through the background and basics of the Improvement Kata and Coaching Kata, and worked to tie that in to what they observed in their visits to local companies. They were a great, engaging group that was fun to work with.

One thing I do to close out every session I do with a group is ask “What did we learn?” and write down their replies on a flip chart. I find that helps foster some additional discussion and consolidate learning. It also gives me feedback on what “stuck” with them.

Sometimes I get a gem that would make a good title for a blog post. The title of this post is one of those.

Think Big

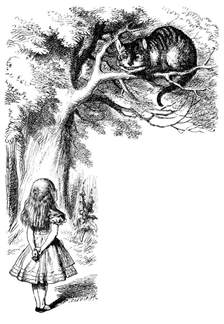

Alice went on, “Would you tell me, please, which way I ought to go from here?”

“That depends a good deal on where you want to get to,” said the Cat.

“I don’t much care where…“ said Alice, “…so long as I get somewhere,” Alice added in explanation.

“Oh, you’re sure to do that,” said the Cat, “if only you walk long enough.”

The question, of course, is whether or not where Alice ends up is where she intends to go. A lot of continuous improvement activity takes this approach – Look for waste. Brainstorm ideas. Implement them. Just take steps. And, like Alice, you will surely end up somewhere if you do this enough.

I had a former boss (back in the late 90’s) advocate this approach. “We are painting the wall with tennis balls dipped in paint.” The idea, I think, was that sooner or later all of the splotches would start to connect into a coherent color. Maybe. But, at the same time, he was also very impatient for tangible results. Actually that isn’t true. He was impatient for tangible activity which is not the same thing at all.

Direction and Challenge Establish Meaning

In her journeys through Wonderland, Alice learns that objective truth has no meaning in a world of random nonsense. The story, of course, is a parody of the culture and times of Victorian England. It does, however, reflect the frustrations many practitioners can feel when they are just trying to “make improvements.”

As one thing is “fixed,” another pops up for any number of reasons:

- The “new” problem may well have been hidden by the “fixed” one.

- Leadership may be chasing short-term symptoms and constantly redirecting the effort.

Day to day it just seems like random stuff, and can get pretty demoralizing.

The point of “Think Big” is that being clear about where WE (not just you) are trying to go helps everyone understand the meaning of what they are doing. That is the whole point of “Understand the Direction and Challenge” as the first step of the Improvement Kata. “What is the meaning behind what you are working on?” It is really a verification check by the coach that the coach has adequately communicated meaning to the learning.

Establish “Why” not “What”

At the same time, it is important for the organization to be clear on why improvement is necessary. I have discussed this a number of times, but keep referring back to Learning to See in 2013 where I ask “Why are you doing this at all?” as the question everyone skips past.

“Where we are going” should not simply be your model of your [Fill Company Name In Here] Production System.

No matter how well explained or understood, a model does not directly address the “Why are we doing this at all?” question that provides meaning to the effort.

It may well establish a good representation of what you would like your process structure to look like, but it does not give people any skill in actually putting these systems into practice, nor a reason to put in the effort required to learn something completely new.

Change Small

Small changes = fast progress as long as there is a coherent direction.

The classic 5 day kaizen event is often an attempt to make a radical improvement in a short period of time. Things usually look really impressive at the end of the week, and even into the next few weeks. What happens, though, is that the follow-up is usually more about finishing up implementation action items than it is working to stabilize the new process.

The problem comes from the baseline assumption that we already understand all of the problems, and our changes will solve them. We line things up, get 1:1 flow running, and yes, there is a dramatic reduction in the nominal throughput time simply because we have eliminated all of the inventory queues.

There is tons of research that backs up the assertion we can’t expect people to be creative when they are under pressure to perform. They are going to revert to their existing habits. During the event itself, the short time period and high expectations put pressure on people to just implement stuff. People are likely to defer to the suggestions and lead of the workshop leader and install the standard “lean tools” without full understanding of how they work or what effect they will have on the process and people dynamics.

Come Monday morning, we put all of those changes to the test… at once. The people are working in a different way. The problems that will be surfaced are different. The tighter the flow, the more sensitive the system will be to small problems. It is pretty easy to overwhelm people, especially the supervisors who have to decide right now what to do when things don’t seem to be working.

That same pressure to perform exists, only now it is pressure to produce, and possibly even catch up production from what was lost during the previous week. Once again, we can’t expect people to think creatively when these new issues come up, they are going to revert to what they know.

When we do see successful “big change” it is usually the result of many small changes that have each been tested and anchored.

So why is the “blitz” approach so appealing? I think I got some insight into the reason in a conversation with a continuous improvement director in a large corporation. He had so little opportunity to actually engage and break things loose that, when he did, he felt the need to push in everything he could.

My interpretation of this goes back to the first line above: Small changes = fast progress as long as there is a coherent direction. In his case, there wasn’t coherent direction. He had a week, maybe two, to push as hard as he could in the direction he felt things should go. The rest of the time, things were business as usual.

This is why “think big” is important. It provides organizational alignment, and reduces the pressure to seize a limited opportunity and, frankly, inject chaos.

Small, Quick Changes

Because we often don’t see just how long it takes to stabilize a “quick, big change,” we tend to think that quick small changes are slower. I disagree. In my experience the opposite is true.

When there is a clear Challenge and Direction, and frequent check-ins via coaching cycles (or less formal means) on what changes are being made, no time is wasted working on the wrong things.

When small changes are made and tested as part of experiments vs. just being implemented, then there is less chance of erosion later. Rather than overwhelming people with all of the problems at once from a bunch of changes, one-by-one lets them learn what problems must be dealt with. They have an opportunity to always take the next step from a working process rather than struggling to get something that is totally unfamiliar to work at all.

That, in turn, builds confidence and capability.

In a mature organization that has practiced this for years, an outside observer might well see “big changes” being made. But that organization is operating from a base of learning and experience, and what might look big to you might not be big to them. It is all a matter of perspective.

What Do You Think?

I’m throwing this out there, hoping to hear from practitioners. What have you struggled with getting changes made that actually shift people’s behavior (vs. just implementing tools and techniques). What has worked? What hasn’t worked? I’d love to hear in the comments.

Mark,

Isn’t Shingijutsu known for coming into a plant and on the same day, and begin moving major production equipment around? Isn’t that a large-scale change that could be a shock to the system? When do substantial, rapid changes to a production floor make sense?

From own experience (inside distribution centers), I have seen great ideas and lots of enthusiasm generated from 3-4 day Kaizen event, only to see nothing happen or a regression to old habits because there was no leadership and long-term plan to sustain and learn from the improvements.

However, I have also seen personal success in completely changing a high-touch, manual kitting line in one day. No kaizen events, no meetings to discuss, no in-depth analysis, etc. The local ops team and myself just did it and saw tremendous success and to this day, they still operate the same way. However, I would say that case was the exception and I have often reflected upon *why* we were so successful in that situation.

Jason – yes, Shingijutsu is known for that.

But in reality, the experience is more based on the client’s preparation, objectives and response.

I, too, have seen cases where quick changes worked.

I have seen many more cases where they faded into the background noise – including Shingijutsu workshops.

The question really comes down to this:

Who is learning?

What are they learning?

We have to remember the critical role of the direct supervisor in these operations.

If the supervisor is simply doing what he is told because that is what someone told him to do, we are unlikely to see sustainable change.

If, on the other hand, the supervisor of the area has been set up for learning by the home / client organization, then the Shingijutsu experience can be intensely rewarding.

So… in the end, if the organization is pushing “lean” for lean’s sake, without a performance objective, it is unlikely much learning will take place. If, on the other hand, the supervisor is struggling to meet a challenge of some kind, and the workshop is “We want to help YOU succeed” then the results may well be different.

Also – an organization, any organization, has a maximum rate that it can absorb change. We often see organizations that are really good at change and try to get there right away because they can do it. In reality, they got good at it because they practiced it. We don’t usually see that part.

The best baseline?

An organization that is striving, pushing a little every day. Send a Shingijutsu consultant into there, and that organization will up their game when challenged by the consultant.

An organization that is just going through the motions, saying “Oh ****, Shingi is here next week, what are we going to do?” is unlikely to sustain much of what they learn. They are just trying to survive the week and get back to the real stuff they have to do. They aren’t “bad” for that. They just aren’t set up to succeed.

“The problem comes from the baseline assumption that we already understand all of the problems, and our changes will solve them. ” I see it all the time; a looong list of actions – after which we expect to arrive at a very specific known solution. Kata is much more about testing solutions in the general direction, leading to a new target conditions and eventually arriving at a solution which we at best had just a vague idea about in the beginning.

I’ve been preaching Think Big, Act Small for years now, having seen some of these problems… over engineered solutions for k=1, only to find they were way off for k=2.

Watch out for missing some big-win opportunities though.