Tyson Ortiz

Tyson zeroed right in on one of the biggest problems with “training” – getting people to adopt the new process or method after we have taught it to them.

Compounding this was that, in his example, the training was TWI Job Instruction – how to train. Tyson took a quick show-of-hands poll and informally confirmed his hypothesis that most people who take the TWI Job Instruction 10 hour course are already engaged in training and teaching.

This means that they have to do more than learn a new habit – one which will feel awkward to them at first. They also have to unlearn their current way of doing things – a way that is likely comfortable and familiar to them. To paraphrase from a slide of mine that seems to keep coming up: This. Is. Hard.

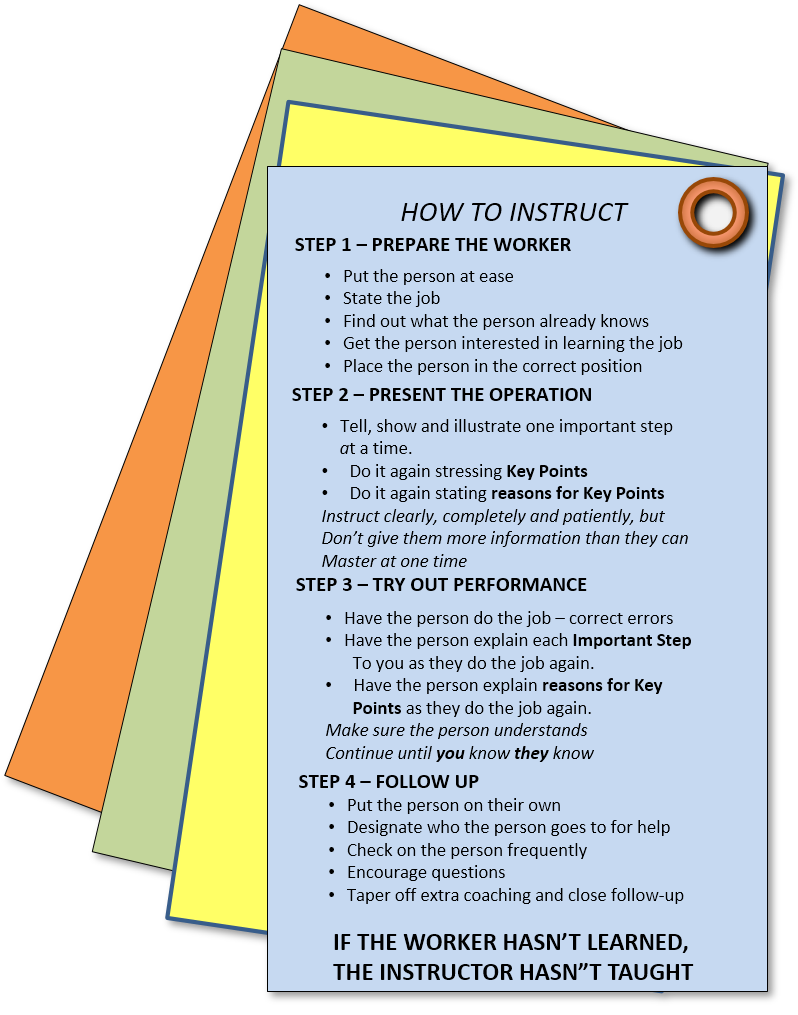

Taking what he has learned from Toyota Kata, Tyson saw the 4 Step Method for what it is: A routine for practice, not the end-all. For that to work, there must be actual practice using the routine. The 10 hour class is telling them about it* – and telling alone is not enough!

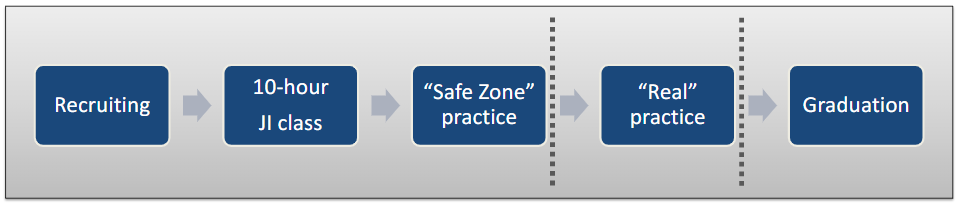

What Tyson did was add structured follow-on practice with real work, but not real training where the participants can practice, make mistakes, and learn in a safe environment. Then they move to live environments, but are still being coached. Then they are graduated and put on their own.

Another key is that passing each stage is based on performance, not a time line. It is up to the coach, since the coach is the teacher, and “If the student hasn’t learned, the teacher hasn’t taught.”

*Yes, the class includes demonstrating the four steps – but each participant typically only gets one repetition, hardly enough for us to know that they know.

Roger Bilas

Roger actually built on the theme that Tyson was developing – the process of getting Job Instruction incorporated into the daily routine of the organization.

We often call this “managing change” or more cynically “overcoming resistance” but I think both Roger and Tyson are operating at a much more fundamental and human level. It’s called paying attention to what is causing stress and fear and make sure you deal with it effectively and with empathy.

And it is empathy where Roger begins.

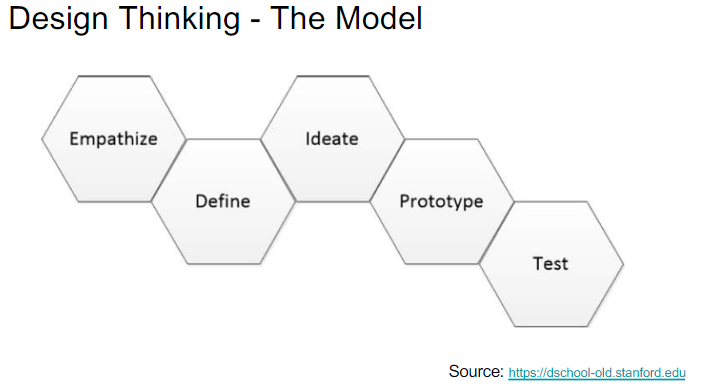

He used the Stanford design school model to experiment his way toward a solution that used the framework of Job Instruction in a way that worked for the particular situation. And isn’t that the whole idea?

As I was listening, I scribbled a note in the margin: “this is Menlo’s model” – the design process that Menlo Innovations. It isn’t really – this model uses different words. But the structure, intent, purpose is the same and is followed by all robust design and product development processes.

Roger was operating in an environment that was unfriendly to paper, had lots of high-variety and low-volume tasks that people had to get right.

Once he understood that he had motivated people in a tough situation, they began working together to develop simple solutions that worked – starting with simple sketches and hand-written notes on laminated cards.

Iterating through, always asking “What small step can we take?” toward the goal, always asking “How can we test that assumption or idea?” they converged on a solution that worked really well.

Not surprisingly, it was very visual and simple, and captured “Key Points” from the Job Breakdown.

There was a lot more good stuff at the TWI Summit. I’ll cover my own keynote separately. And I missed the 3 hour “Experiential” sessions because I was presenting one. And for the afternoon of Day 2 I was attending Oscar Roche’s version of a Toyota Kata class that follows the 5 x 2 hour structure of the classic TWI JI, JR, JM classes.

Thus, the next big thing for me to report on will be KataCon – which will be my next post.