One of the things Menlo does (and I am sure they are not the only ones in their business who do) is create user personas – a biographical profile of a fictional person who represents a category of potential user for the software they are developing.

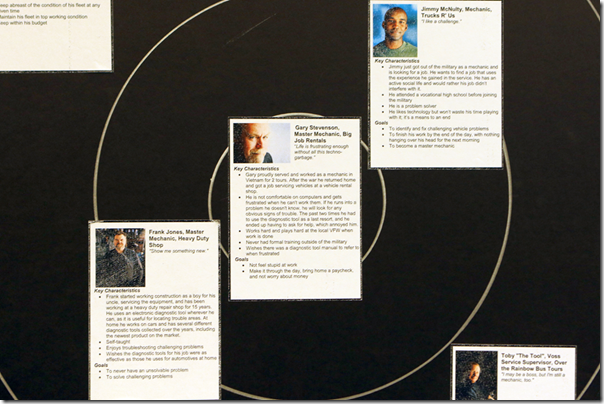

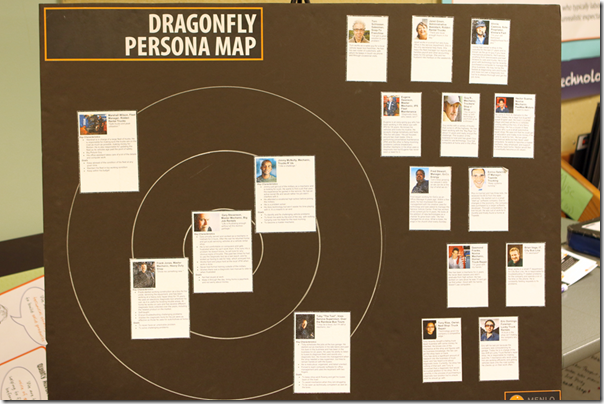

In Joy, Inc, Rich Sheridan describes the often contentious process of then forcing the customer to pick a single persona as the primary user – the persona whose needs will drive all decisions about optimization. That person goes in the center of their three rings.

They allow two personas in the 2nd ring, and three in the 3rd ring.

As they make design decisions about their code and user interface, they always defer to the innermost rings. That doesn’t mean that someone in a ring further out won’t have their needs met, but they will meet those needs in ways that don’t compromise the process for personas closer to the center.

Persona Mapping for KataCon

In the spirit of being a temporary Menlonian, I worked paired with Craig (over the phone, and in a shared Google Doc) and we developed a persona map for KataCon. Of course, had we done this correctly we would have gone back in time to the previous KataCon, gotten the profiles from the attendees lists, interviewed people, and put together profiles for “typical” people who attend.

Since we couldn’t do that, we pushed past our threshold of knowledge and combined experience with a bit of speculation. I did confirm some of our assumptions via a phone call to Dwayne at Lean Frontiers who graciously answered my questions as he was driving across Indiana.

This process forced us to actually think about who was in the audience, and why they were there – what they were seeking from their participation in the conference. As Rich and I talked about his message, and later on as Craig and I worked on our “Experiential Workshop” we used the names of these “people” rather than generic terms like “participant” or “audience.” I found that really focused our conversations.

Who Do You Optimize Your Process For?

This really begs the general question: Who is your process optimized for?

Is it optimized for the person doing the work?

For the customer’s specific experience? And if so, who is the “customer persona” you are optimizing THAT for? For example, for an ideal retail experience, a mom with two kids in tow would be a different customer than a single guy. You likely get both, but if you have do something that slightly compromises one in order to optimize the other… who is in the center ring?

Next up: Target Conditions as User Stories