Mike Rother forwarded this link to an article by Bruce Hamilton in Quality Digest with the observation that “the lean ship may be turning.”

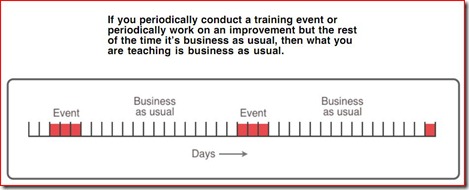

The key point is that people learn what they practice. And if you practice kaizen every day, you learn kaizen. But if you practice something else every day, you learn that. If kaizen is only an occasional “special event” then it never becomes engrained as “the way we do things.”

From the article:

The truth is, when everybody practices status quo behavior almost every day,that is what is sustained. If employees are not practicing the new way every day, by default they are practicing the old. Practice makes permanent.

Mike illustrates this principle well in his presentation Introduction to the Improvement Kata.

In reality, rather than days between events, the experience of the team members is more often like weeks or months. Some companies set a goal of getting every team member through one or two kaizen events in a year.

While this may spread the effect wide, it ensures that nobody has more than superficial experience. It is build on an expectation that once a process is “leaned out” that it should stay that way until there is an opportunity to come back around and “fix it again.”

Of course it actually begins to erode right away because the daily habits have not changed, and it is those daily habits that put the waste into the process to begin with.

The traditional model for kaizen is firmly anchored in Fredrick Taylor’s concept of separating experts from workers. Even though we solicit worker’s input during kaizen events, the process of kaizen itself is still largely the domain of technical experts. They are the ones who own the process.

Some companies go so far as to not allow kaizen to be done by people who are not “certified” in some way.

What we have to do is shift the role of those kaizen experts from one where they plan, conduct and lead special improvement events to one where they are on the shop floor every day teaching and coaching the line leaders. This is the only way (that we know of) that will actually transfer the knowledge.

Only when those line leaders are, themselves, teaching and coaching can the effort let up a bit and move on.

The “ship may be turning” because this idea is beginning to find its way into the mainstream discussion in the lean community. This will not happen overnight, however. There is huge inertia in the expert-as-implementer mode across all approaches to improvement. But if we (the lean practitioners) want to know why the results do not sustain, a large part of the answer is in the mirror.

“If the worker hasn’t learned, the teacher hasn’t taught.”

One Reply to “What Do You Teach and Practice Every Day?”