Outside of the actual operation, the default meeting schedule for most organizations is weekly.

This is OK when everyone understands what is expected and the default thinking and behavior is working for you.

With Toyota Kata, though, the intent is to practice a routine that is not default thinking or behavior. Yet many organizations fall into the default of a weekly coaching cycle.

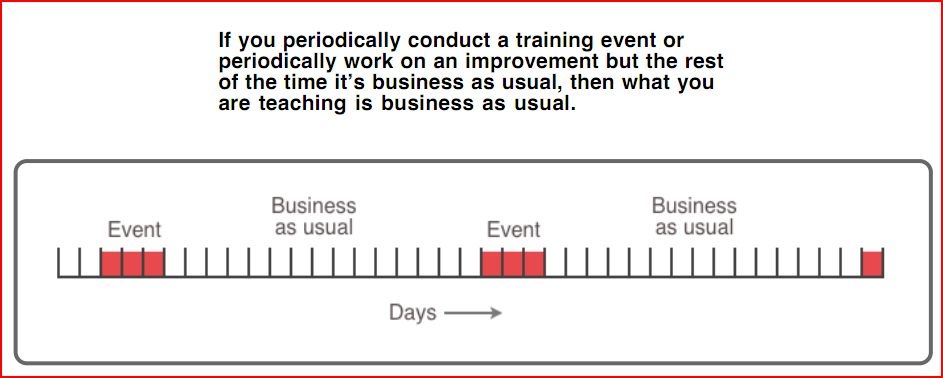

What we have to remember is that the coaching cycle, and the learner’s preparation for the coaching cycle, are practice. The time(s) that you aren’t practicing you are engaging in the default, and if the default isn’t what you want it to be then it will easily overpower what you are trying to learn.

15 minutes a day is practice. 15 minutes a week is dabbling.

It is the same as a supervisor’s area experiencing one or two “kaizen events” a year. It is just dabbling with kaizen, not practicing it every day, and certainly not immersion. They aren’t going to learn to think differently with that kind of cadence.

Batch Production of Experiments

One of the reasons we want to drive toward one-by-one flow in production is so we can have one-by-one confirmation of products vs. waiting for a huge batch to be produced only to discover that they all have problems.

Breaking it down even further, we want one-by-one confirmation of operations so that we don’t keep working on something that is already unusable from something earlier.

Likewise, if a learner is running many experiments without checking in with a coach, he can get pretty far off track without realizing it. The coach can provide a valuable outside check to make sure the learner isn’t getting locked on to something that is distracting him from the bigger picture.

Remember: This is about developing people

Before you jump in and say “But I don’t have time…” consider the alternative.

How much time do you, as a manager, spend intervening in problems that you think people should be able to solve on their own? If you keep giving them the answers, they are going to keep brining those issues to you.

With a little bit of thinking, the Coaching Kata cycle can be easily spliced on to David Marquet’s “Ladder of Leadership” and guide your conversations away from intervention and toward creating able problem solvers.

But before you can do that well, you have to practice the Coaching Kata until asking those types of questions becomes second nature to you.

This isn’t all about the learner’s development! If you only practice coaching once a week, whatever your default is today will likely remain so tomorrow. Change requires repetition and practice.

Just some things to think about this week.

Obstacles are stones in the way, not a reason to give up on your goal. In fact, obstacles can be useful because they show you what you need to work on to achieve your goal.

Currently not having time for daily coaching cycles is an obstacle, not a reason not to do it. Plug it into the Improvement Kata pattern and iterate your way to daily coaching cycles. Many thousands of coaches have done exactly that.

Well said, Mike.

Your response actually reinforces one of the benefits of an outside coach who has already internalized the pattern.

For an organization where coaches as well as learners are beginners, they might not yet see everything in the way as an obstacle.

Thoughts?

I agree, Mark. The coach doesn’t give solutions but, having traversed similar territory themselves, they know better what may be possible and can give the learner appropriate corrective inputs and encouragement, which keeps the learner moving toward their goal via effective scientific iteration. It’s not an unbroken straight line of successful steps, of course. Quite the contrary: we learn from what doesn’t work. Once the learner has successfully gone through that a few times a world of potential opens up for them. The best feedback a coach can receive from the learner is, “I don’t know why you were here, I did it all myself.” And the coach has to be happy with that. It’s a tough job. 😉

Hi Mark,

This blog post really resonated with me, especially given that I am working on my lean six sigma green belt project right now. I especially liked what you have to say about the need for consistently checking in with your coach. I have found while working on this project and on projects in the past, that if the guidelines are not clear and you don’t regularly check in with your manager or team mates, it is very easy for operations and experiments to get far off of track. Outside checks are definitely very important and I think it is important for managers, teachers, leaders, and coaches to make their employees and students feel comfortable with asking for check-ins and assistance.