Gipsie Ranney is a consultant with The Deming Cooperative.

A white paper she recently wrote, contrasting NUMMI with The Big Three, has been circulating by email. I requested, and received, her permission to publish it here.

Remembering NUMMI

Gipsie B. Ranney

January, 2009

The discussions of a bailout for the U.S. owned auto industry – The Big Three – and the recommendation that a czar be named to oversee them so that they don’t waste U.S. taxpayers’ money has led me to think about an experience I had in the early 1990s. I had the opportunity to tour the New United Motor Manufacturing (NUMMI) factory in Fremont, California. Thinking back on that experience has led me to wonder how much good an injection of cash would do.

Much has been written about Toyota’s production system, but my observations on that visit may help to shed additional light on the differences between Toyota and The Big Three and what the likely outcome of attempts to cure what ails The Big Three may be. As you probably know, NUMMI was established as a joint venture between General Motors and Toyota. Middle management personnel from GM were sent to NUMMI to spend time learning about how Toyota did things. The tour I made was conducted by some of those GM employees. As I understood it, the GM employees who were sent to NUMMI were required to write at least one white paper about what they had learned. Rumor had it that only a few people back in GM ever read those papers and employees who came back to GM from NUMMI found themselves unable to get back into the career progression at GM, so there were few who volunteered to go after the initial volunteers. This led me to believe, after my visit, that perhaps the best opportunity GM would ever have to learn something useful was being thrown away.

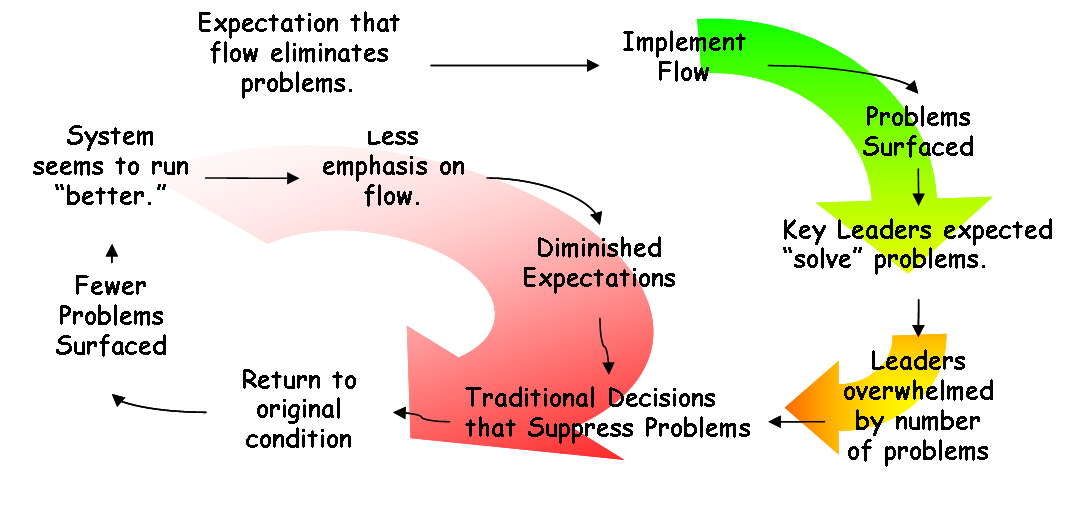

Before the tour, I didn’t think I was going to see anything remarkable. I thought I would confirm my belief at the time that all The Big Three had to do was get busy on improvement and all would be well. I came away shaken by what I learned. The most important things I learned were about thinking. Toyota clearly thought differently about producing vehicles. Whether they have maintained these ways of thinking in spite of opportunities to be diminished by adopting the practices of The Big Three will have to be answered by someone else.

Before the Fremont factory had been turned over to NUMMI, I was told it had the worst record of management/labor conflict of any U.S. automotive plant. Now, management/labor conflict was nearly non-existent. Further, I was told that among the assembly plants connected to GM, the NUMMI factory (since Toyota entered the picture) had the best quality record, although it had the worst quality record of any Toyota assembly plant. It was my understanding that the top management of the NUMMI factory were Japanese, as were the engineering staff.

The first area we visited in the factory was the incoming materials warehouse. This warehouse was devoted to parts and materials supplied within the United States. Of course, the warehouse had visual controls. There were areas painted on the floor with signs over them that said how much of what items should be there. As I recall, supplies came into the warehouse on a four-hour cycle; that is, suppliers shipped enough of an item to last for four hours. These supplies would be on their way somewhere in a new vehicle in four hours. This was part of the JIT (Just in Time) materials supply system that has been copied throughout the U.S. (I was amused at the time by ads I saw in airline magazines offering to warehouse a supplier’s parts and send them JIT to their destination. This was a new, more expensive version of the push system for production and management of inventory that I suspect still exists.)

The answer to a question asked by someone else on the tour was stunning to me. The person asked what kind of computerized inventory system they had at NUMMI. The leader of the tour at the time – a materials management person – responded, “we don’t have one; the Japanese say that computerized inventory systems lie.” I was somewhat familiar with inventory at Big Three factories. Huge inventories of component parts were maintained. It sometimes took days of shut down to do a complete physical count of inventory. We were told that NUMMI could do a complete physical count in four hours – that made sense, since that was generally all the inventory that was there except for parts shipped in from Japan. Why the huge inventories in Big Three factories? Partly because the production system was a push system – vehicles were built to satisfy sales forecasts that were often overly enthusiastic, and partly because the parts were there Just in Case. If there was a failure on the production line, there needed to be lots of spare parts to keep production going. I had heard horror stories about production lines that were halted for lack of parts that were the right size, even though there were hundreds of thousands of parts – of the wrong size – in inventory. I had consulted with several companies that had a very difficult time matching up the records of inventory in their information system with the actual physical inventory. That is, the computerized inventory system contained “lies.” They spent a lot of time and effort trying to decide what the correct numbers were. As a result of the design and operation of their production and supply systems, NUMMI was able to avoid the expense of the computerized record system and the expense associated with management of huge inventories. Whatever was spent trying to keep the records straight and keep track of where the parts were in Big Three factories was not being spent at NUMMI.

A friend commented that he believes the material flow system used by Toyota may provide their biggest competitive advantage. In American manufacturing systems, one of the first steps in providing for material needed to produce a product is to create a Bill of Material (BOM) based on the design of the product. The BOM lists all of the parts needed; for example, a car needs one engine, four wheels, one catalytic converter, one steering wheel, two headlights, and so on. When the production of one car is planned, the BOM is used to order all the parts needed to produce the car. When the parts arrive, the appropriate electronic records of inventories are altered accordingly. Then when the car is produced, the BOM is used to delete the parts used from the inventory records. This is known as “backflushing.” Engineering changes involving changes to part content of a product should lead to corresponding changes to the BOM. When this doesn’t happen accurately or soon enough, use of the BOM and backflushing leads to accumulating errors in inventory records and incorrect orders. The result is computerized inventory systems full of “lies.” One company expects to save approximately ninety percent of the cost associated with inventory by switching to Toyota’s Kanban system. My friend pointed out that the Kanban system is self-correcting and does not require the labor hours, elaborate information systems, and inventory expense associated with traditional systems of material management. Another friend pointed out that many of the practices Toyota uses to manage material may have been adopted by The Big Three. That may be the case, but this example illustrates differences in purposes, concepts, and questions, and therefore methods, that can exist in organizations’ approaches to their work.

Use of the traditional approach to materials management and the consequent cost of inventory leads to distraction of the management that prevents them from addressing issues of greater importance to the future of the enterprise. The statement, “you can’t manage what you don’t measure” has become a mantra for American business. But, as a friend has observed, when one decides to measure something and attaches a meaning to the measurements, one has framed the questions to be addressed and defined suitable answers. NUMMI had no interest or need to keep detailed records of inventory. They had changed the question from “how do we manage inventory and reduce inventory cost?” to “how should material flow through the system?” The Big Three could gain great benefit from asking themselves what the important questions might be. I have often wondered how often managers of American businesses fall into the trap of using existing measures for no other reason than because they are there – required by regulation or for tax reporting purposes, rather than deliberately choosing indicators that will help them manage. Questions should precede answers.

At NUMMI, some automobile components were imported from Japan. One of these was the engine. Another person on the tour told us that a materials director at the engine division of a Big Three company had just issued an edict that the purchase price of every part being supplied from other divisions and outside suppliers had to be reduced by exactly the same percentage in the next year: ten percent. While touring the area where engines were inserted into the vehicles at NUMMI, the tour guide related that the Japanese had evaluated the importance of every engine component to the proper functioning of the engine. He said that they would then attempt to reduce the purchase price of components that were not as important while they invested resources in improvement and perhaps paid a higher price for components that were critical to reliability. The contrast between the foolish edict to reduce the prices of everything by the same percentage and the intelligent consideration of functionality and reliability of the product was another example of a difference in thinking – Toyota’s approach being far more mature.

In the stamping area, we learned that the same approach was used to design and build the dies that were used to stamp parts of the vehicle body. The material used on the surface of the die was very expensive, but extremely hard, while the other parts of the die were far less expensive than what was used in US companies. NUMMI’s dies served longer and were, overall, less expensive to build. These two examples illustrate the notion of optimizing an entire product system in terms of cost and performance, rather than sub-optimizing by trying to minimize each individual component’s up front cost. These are different ways of thinking about purpose and method.

At the time I visited, the NUMMI factory was not highly automated in terms of the use of robots. We saw robots helping factory workers put the seats in vehicles. We were told that robots were not used in the factory to replace workers; they were used to assist workers when the work was physically very demanding or difficult. I was reminded of a Big Three assembly plant where robots were installed to replace the welders who welded the frames of vehicles together. After a short time, the robots were removed and replaced by humans. The reason was that there was so much variation in the components coming in to be welded that the robots got confused and were making pretzels instead of frames. The human welders had been adjusting to that variation for years.

The replacement of people by machines is a favorite method used in the U.S. to affect accounted costs. However, direct labor is often the least expensive per hour kind of labor in a company. Machines must be maintained (or should be) and the software associated with automation and other computer operated equipment must be revised to accommodate changes in production processes. The labor expense associated with these activities is often more expensive per unit time than direct labor. Some of these expenses even show up as engineering or information systems expense. Sometimes, humans are needed instead of automation run by software because they are more adaptable and more easily maintained. The more complexity in any production system, the more opportunities there are for failure. The point here is that choices made in the design of a production system must be considered from a total system viewpoint, rather than from a simplistic, accounted cost viewpoint. I understand that Toyota’s new U.S. factories are highly automated. I would expect them to have been sensible about the design of these systems and to consider the possible consequences of their choices.

Lots of attention is paid to the cost of labor, and labor cost has been a favorite excuse for lack of competitiveness. But the options for ways to be non-competitive are limitless. I was told that one of The Big Three required that measurements on approximately 1200 “key indicators” were required to be reported to the central administration monthly. There were probably thousands of people accounted for in overhead doing the work to make those reports. There were not enough executives in the central administration to review all those numbers and probably a rare few of them knew what to make of the numbers if they did review them.

There is no question that existing obligations are major factors in the financial problems The Big Three are having. It is interesting that the big focus is on organized labor and the obligations for benefits to salaried retirees are not discussed nearly as much. The UAW certainly isn’t lovable, and the concessions they have obtained in terms of pay and benefits have been enormous and seriously detrimental in the long run. But one question keeps coming to my mind with regard to those concessions. Did the UAW simply issue an edict that there would be concessions? Of course, the answer is no. It takes two to make a contract and the management of The Big Three agreed to those contracts with the UAW. Surely there was someone in the management of each company that did some computations to see what the concessions would cost the company in the short term and the long term. I suspect that there was an extreme desire each time a new contract was negotiated to avoid a strike. After all, a strike would happen right away and would affect that year’s bonuses, but the consequences of the concessions would come to roost in the future and it would be more difficult to find someone to blame.

The central administrations of The Big Three tend to issue edicts to their organizations about what performance is expected. An edict issued in one of the companies stated that warranty cost was to be reduced by fifty percent this year to next year. The design and testing of a vehicle and its components takes several years. Major redesigns are not done every year. Major components are often carried over from one year’s vehicle to the next. The designs of vehicles and production systems for next year were already completed. How could such a reduction be achieved? Obviously, the individuals responsible for the edict were not thinking clearly about the constraints the nature of their business placed on performance. Of course, one “reason” for high warranty costs that regularly surfaced was that the dealers were cheating. So the edict to cut warranty cost by half may have been aimed at making the dealers behave.

Are we beginning to see a pattern here? Problems that are assigned to suppliers, direct labor, and dealers as sources of non-competitiveness appear to me to be manifestations of what Peter Senge called “The enemy is out there.” According to this view, some of the problems of non-competitiveness that are due to poor thinking and poor decision-making are ignored and the blame for all problems is assigned to some other group. If in no other way, we could all follow Michael Jackson in this regard and “start with the man in the mirror.” Reflection on one’s own role in one’s situation is difficult, but seems to be critically important to avoid repetition of the same mistakes.

I have not discussed what I saw in production at NUMMI in any detail because Toyota’s production system has been analyzed many times. One aspect of NUMMI that I thought was very important was management of the labor force. We learned that direct labor on the production line had secondary jobs that they were supposed to do if and when the production line stopped. They would do various equipment maintenance tasks and cleanup tasks. My understanding of Big Three direct labor is that production workers have no responsibility for maintenance; they have quotas for a shift’s production, and when they complete their quota they can go sit in the cafeteria or find a place to sleep. The management of NUMMI was able to negotiate an agreement with the UAW that enabled the assignment of auxiliary tasks to workers, but apparently the management of The Big Three were not.

As I understood it, there were work groups in production at NUMMI that rotated among different jobs in an area. There were levels of qualification that could be achieved by an individual worker for each job in the area. As a worker gained more training and experience, he or she was able to move up to the next level of qualification. The highest level of qualification was “teacher” or “instructor” or something similar. The work groups had improvement projects that they worked on. Their tasks involved improving the quality of the output of their area, or improving efficiency, or making the work easier to do, or all three. If they were able to demonstrate that their ideas for improvement were good, they would be implemented. As I saw it, these aspects of the organization of work helped to enable people to be engaged and to have a sense of contributing to their joint enterprise. At times, there may be too much focus on the technical aspects of the Toyota production system (lean, JIT, …) and not enough on the culture. The commitment that comes from personal pride in one’s work is a critical, but unmeasurable, aspect of any employee’s contribution to the enterprise.

The most remarkable insight I gained at NUMMI came as an answer to a question from a member of the touring group. The person asked what had been learned about the reasons that management/labor conflict had been reduced so much. The tour guide answered, “The answer we get from members of the labor force is that the Japanese do what they say they will do.” This was the same labor force that had held the record for most grievances filed per year in an assembly plant in the U.S. To me, this says a great deal about trust. There are circumstances in which you can trust a manager to be generous or kind or helpful; there are circumstances in which you can trust that manager to be harsh or intolerant of certain behaviors. In both cases, the manager who can be trusted to behave as you expect may be preferable to a manager who is unpredictable and cannot be relied on to provide the resources you need to do a good job. Some consultants imply that all managers need to do is to be nice to people and everything will be O.K. I doubt if that is sufficient.

Several months ago, I remarked to a person who deals with 401K investments in a very large financial management company that I didn’t think investments in American car companies would be a good idea. He remarked that I was wrong since they were coming out with some great new products that would be fuel efficient. I don’t think he knew very much about the nuts and bolts of building cars and trucks. The new products would at first only be a drop in a giant bucket. It takes years to develop and test new vehicles and to retool factories to produce them. The Big Three had equipped themselves to continue producing SUVs and other fuel guzzling products that were becoming more and more unattractive as gas prices shot up. As a friend remarked, redesigning a car is not the same thing as redesigning the label on a soup can. Equipping a production line to build a car is not the same thing as printing a different label. Of course, this may change in the future as more flexible factories are built. The point of my rambling here is that the press and Congress are talking about redesigning the automotive industry in the U.S. when I suspect very few of them are qualified to do that. I think it would be preferable to have members of the Toyoda family do it – wishful thinking, I’m sure.

After World War II ended, Toyota had, or created for themselves, the luxury of taking time to think, to experiment, and to learn with the conscious aim to improve their capabilities. If The Big Three were not in such a state of emergency, they could profit by asking questions aimed at sustainability and improvement, such as: What is important to our customers? (This requires actual research, not just speculation or the use of company mythology.) What kinds of changes do we expect in the future that might change what our customers need and value? What changes do we expect that will impact our ability to serve the needs of our customers? How can we improve our relationships with our suppliers and our customers? How can we make our work easier or simpler? How can we design the work so that it flows better? What products or processes need improvement? How can we improve the interactions that take place between departments? How can we more wisely use performance indicators and the information they provide? As it is, The Big Three seem not to have the luxury of careful thought.

The Big Three, and the entire international automotive industry, are in deep trouble at the moment. They are certainly not responsible for some of the trouble they are in. But The Big Three are responsible for managing their organizations wisely. I think that will take more than money. It will take a different culture and a different mind.

Needless to say “Remembering Nummi” got some legs under it.

Needless to say “Remembering Nummi” got some legs under it.