Shortly after 9am last Friday my home Internet went down. After doing my own troubleshooting, I was pretty certain it wasn’t anything in my control, so I called the technical support line of my provider.

The person on the other end (who I later in this saga learned was in the Philippines) was obviously reading a script as we went through reporting which blinkenlights were working (and not working) on the interface box (ONT – Optical Network Termination), doing a power cycle of same, “While ..we.. are.. waiting,.. Mark,.. how.. is.. the.. weather.. there.. in.. Everett?”

Whatever remote diagnostics they ran apparently didn’t detect anything out of norm with their system, and he said they would send a technician out “between one and five pm.”

Around 3pm I got a call from the technician, and went outside to meet him. He was still in his van in my driveway, obviously looking at something. When he looked up and saw me, he said, “I just figured out what the problem is. Does your interface box have a steady green power light, with the optical light blinking slowly?” Yes it does.

He showed me his notes. He had been sent to a number of customers with similar problems, and had connected the pattern to a couple of common hubs. My hub, apparently, was hub 1004. There was a failure somewhere upstream of those hubs. He left without needing to see anything in my house.

Fast forward a few hours and things weren’t resolved, so I was kind of wanting to know what was going on.

I got on the online chat (via my phone) with the provider, confirmed my account, and just as they wanted to run another (futile) diagnostic, I interrupted the script:

The tech that was sent out here said the problem was upline of hub 1004, do you know what the problem is yet? Long pause, then I got more information:

The card in PON #1 has been replaced, they are still working in the cards in PON #3 and #4.I thanked them for the update.

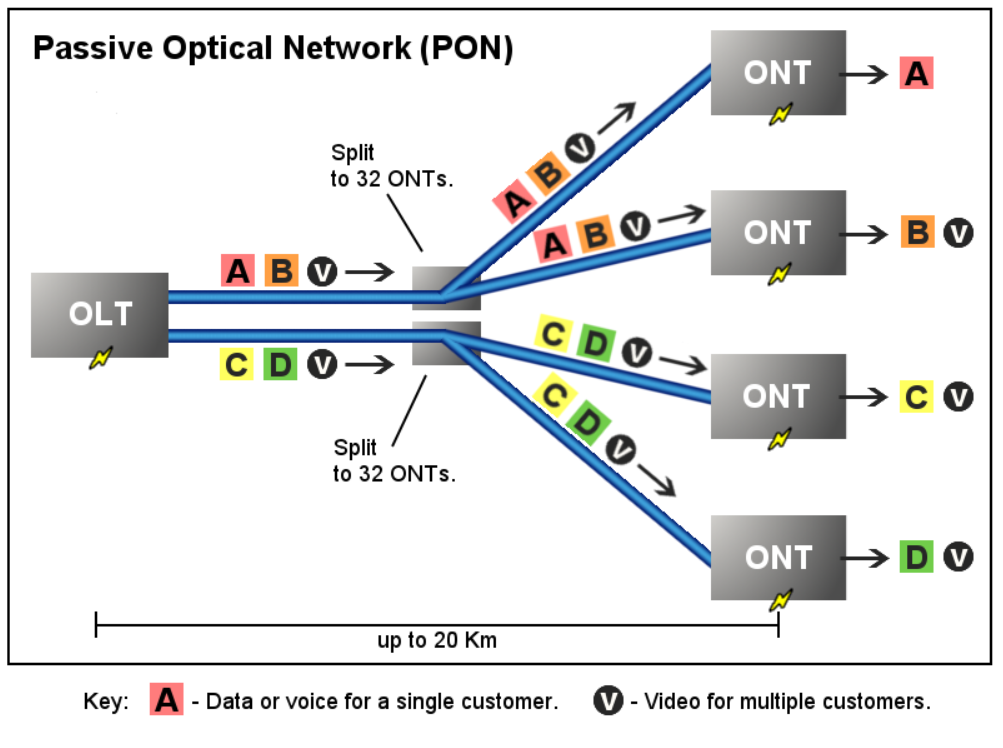

A quick online search (on my phone, no Internet, remember?) told me that a PON is a Passive Optical Network, so they were probably talking about the Optical Line Terminal (OLT). (Again, a little bit of knowledge can be leveraged into more.)

Illustration by user Riick from https://commons.wikimedia.org/wiki/File:PON_vs_AON.png

By leveraging a bit of information that they didn’t expect me to know (that the problem was upline of Hub 1004), I got more information. Now, in this case, that information was not actionable (to me), but it demonstrates how knowing a bit of accurate information can help you get more. If I were working to reverse engineer their network architecture I now have a working hypothesis that Hub 1004 is not part of PON #1 (since that has been fixed, and my Internet is still down), and is downline in either PON #3 or #4.1

What Does This Have To Do With Continuous Improvement Change Agents?

I’m glad you asked. Sometimes, probably most of the time, we are entering situations where we don’t have a great deal of information. And sometimes we encounter situations where people are not particularly forthcoming to our initial curiosity.

Sometimes asking about something specific will invite someone to open up and share more than they might have from a general generic “Can you tell me about this?” question.

If you show you know nothing, it is easier to dismiss you than it is if you show you know something.

This general technique is widely used in the world of intelligence gathering and law enforcement investigations, but it does not have to be deceptive. Having a little bit of information can open up the conversation because it simply shows you have already made an effort to learn.

“I think this process works like this [explain how you understand it]. Is there anything I am getting wrong?” invites the expert to correct your misconceptions rather than having to tediously explain everything from the beginning.

Each additional bit of information can be used to ask a deepening question as you extend your threshold of knowledge.

(Thanks to Craig for adding the following) Don’t be afraid to get it wrong when describing a process. In fact, people often feel more comfortable correcting you than confirming vague guesses. When someone says “no” they can feel more in control and are more likely to offer corrections or additional insights. As a change agent, that’s exactly the kind of dialogue you want.2

At some point, of course, you will likely bump into the threshold of knowledge for the entire organization – the point beyond which nobody really understands how it works. That can be our next obstacle, and the discussion can turn to “What do we need to learn, and what must we do to learn it?”

- Ultimately my Internet was down for about 32 hours, which is much longer than I would have anticipated. I also learned that the call centers get no information at all about estimated time to repair. It isn’t that they won’t say, it is that they are not told.

I will not divulge my ISP in this case since, with this one exception, we have been very happy with the service we get. That being said, if your Google-Fu is good, you probably can leverage the information in this article into figuring out who it is.

↩︎ - This is also a good example of “Cunningham’s Law”: “The best way to get the right answer on the Internet is not to ask a question; it’s to post the wrong answer.” If you are willing to be corrected, you can gain a lot of insight. ↩︎