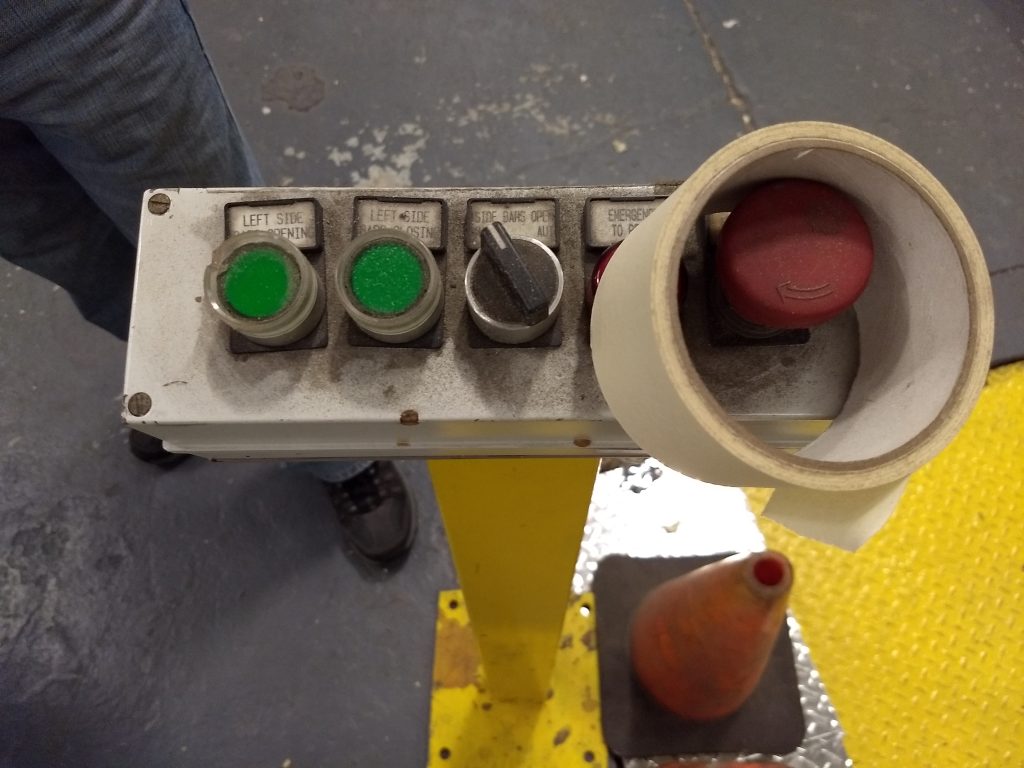

This photo says a lot about the organization. For those of you who might not come from an industrial background, the big red button on this podium is the E-Stop – the Emergency Stop button that shuts down EVERYTHING in the machine IMMEDIATELY.

It is there in case someone is about to get hurt (or worse, is getting hurt). It must be accessible fast so you can just smack it with your palm.

But that isn’t the case here. It is a tape holder. And the tape has to be moved to hit the E-Stop.

Walking around this (now long closed) factory, I saw a lot of this kind of functional disorganization. It was normal. It was, by definition, OK because the leadership (at least those who came out to the shop floor) walked past it every day and didn’t say anything.

I wasn’t there to help fix it, they weren’t a client. I did pick up the tape and suggest to the machine operators that they should find a better place to put it, and why. I did that because I cared for their safety. But the workbench covered 7 inches deep in junk? Interesting, but in this case, the Prime Directive was in play for me.

Take a walk through your organization. What do you see? That is your “OK.”

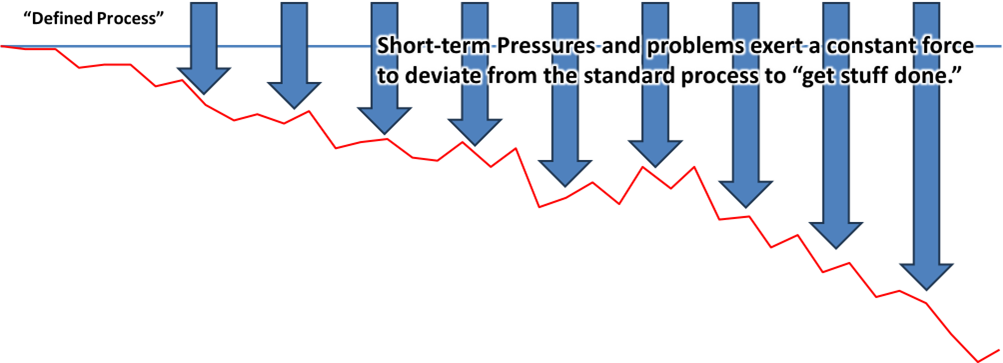

Here’s the model I shared a couple of years ago in a KataCon keynote:

Standards vs. Reality = The Gap

Every organization has a gap between their standards and their reality. What differentiates between high performance and just getting along is the magnitude of that gap.

The gap forms because, left unchecked, all processes begin to erode as soon as they are put into place. As unforeseen issues come up, people left to their own devices will develop work-arounds, add (or omit) steps, and improvise as necessary to do what they believe must be done. They are working hard to do what they believe the organization thinks is important.

We can think of it like this: The blue line represents the defined or aspirational standard. The arrows represent the constant pressures to “find a way to get it done” and the red line represents the steady separation of reality from the defined process.

This downward trend continues until things are bad enough that someone intervenes.

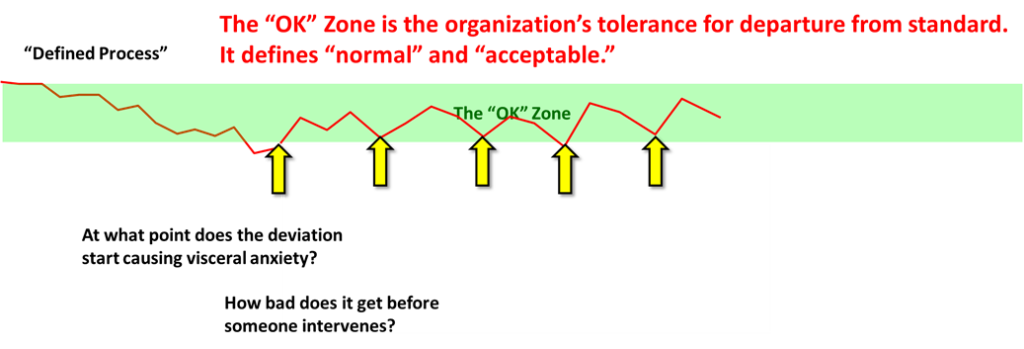

That threshold of intervention exerts upward pressure on the process and maintains it at some level of normal. We have to remember that “normal” means “what we would expect to see.” It doesn’t mean we like normal. It just is.

Anything between the defined process and “normal” and “acceptible” is in your “OK Zone” meaning, “This is OK,” I’m not going to take the time or energy to try to hold it up any higher.

If you want to know what your OK zone looks like, just walk around and look. It is what you see every day.

Unless the intervention threshold changes, any improvements you make will quickly revert to the “OK Zone” baseline.

The question for organizations wishing to up their game and develop a culture of robust execution is: “What would it take to trigger the intervention more quickly, when there is less deviation from the standard?”

The purpose of ALL of the so-called “lean tools” is to highlight the gap, and invite people to do something about it. None of the lean tools intervene on their own, nor correct a deviation, nor actively improve your process. Only people can do that. The tools enable people by giving them the information they need to quickly know when, and how, to intervene, correct, and seek to understand the problem.

One Reply to “What is your “OK Zone?””