I was working with this company mainly on their shop floor processes: Quality, Process Improvement, Daily Management – classic stuff. It was a medium sized plant (a few hundred people) that was part of a larger company with significant business footprints in Europe and North America.

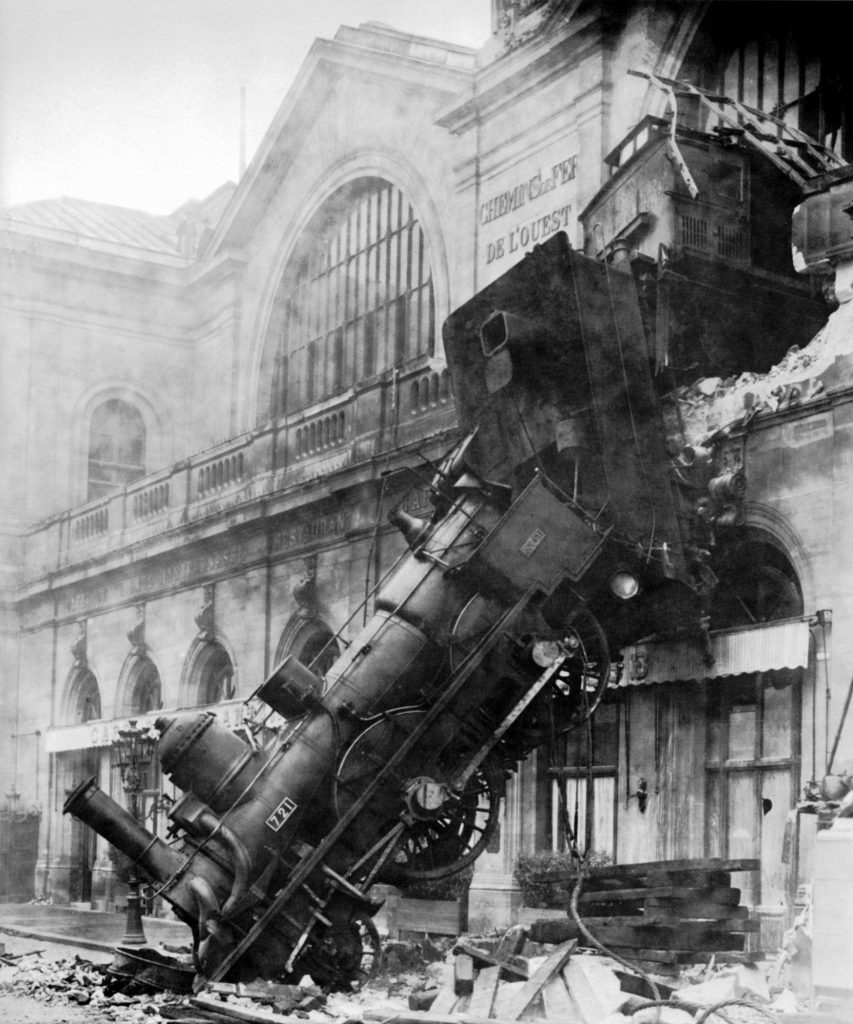

They hadn’t involved me in their upcoming ERP implementation. Heck, they hadn’t even told me they were switching systems. I just heard about it in the course of the day-to-day conversations. My feeling was they were treating this as background noise in their daily business, and I told them. “Focus on this, it will be one of the hardest things you have ever done, and if you treat it casually it will bite you” (or words to that effect).

I was assured that everything was under control.

Over the ensuing weeks I saw a conference room full of outside people all sitting at laptops. I also saw “training” sessions that were mostly lecture and demonstration of the features of the new software. I picked up on conversations that circled around “How will the new system ___(fill in one of their perceived necessary work tasks)___.”

I wasn’t on site on the day the cut over to the new system – and simultaneously cut off their legacy system.

I was on site during the aftermath.

Work orders were released without materials available.

Shipment manifest errors were causing customer rejections.

There were surprise shortages of basic commodity supplies.

The production planners were really struggling.

Sales revenue dropped. Revenue dropped. The bottom line impact was, to say the least, significant.

Corporate’s response was to assemble a team of experts from the global operations and parachute them into this site to get things working.

They asked me to organize that intervention.

We borrowed, and adapted, the daily management process from Menlo Innovations and applied it to this problem.

It’s WORKFLOW, not FEATURES

The first step was to have each stakeholder (the area managers, such as supply chain) to identify, exactly, what problems they had.

We had them write what they thought the problem was. On the first pass, these were usually things they wanted the system to do. In reality, in most cases it was something they didn’t know how to do, but that is getting ahead of the story. Each of those items was written on a single 5×8 inch index card.

Then we had them write their definition of “Solved” as in, “This problem is solved when ___.” and that had to be something that their Team Members could demonstrate back to the stakeholder / manager. We did it this way to make sure that the stakeholder had a clear criteria that, when met, they would verify that this was no longer a problem for them.

Part of that was to remove ambiguity. Part of it was for the stakeholder to accept accountability for the solution vs. saying later that they were not happy.

We then had the outside experts review the cards and accept the ones they would help with.

Now comes the interesting part.

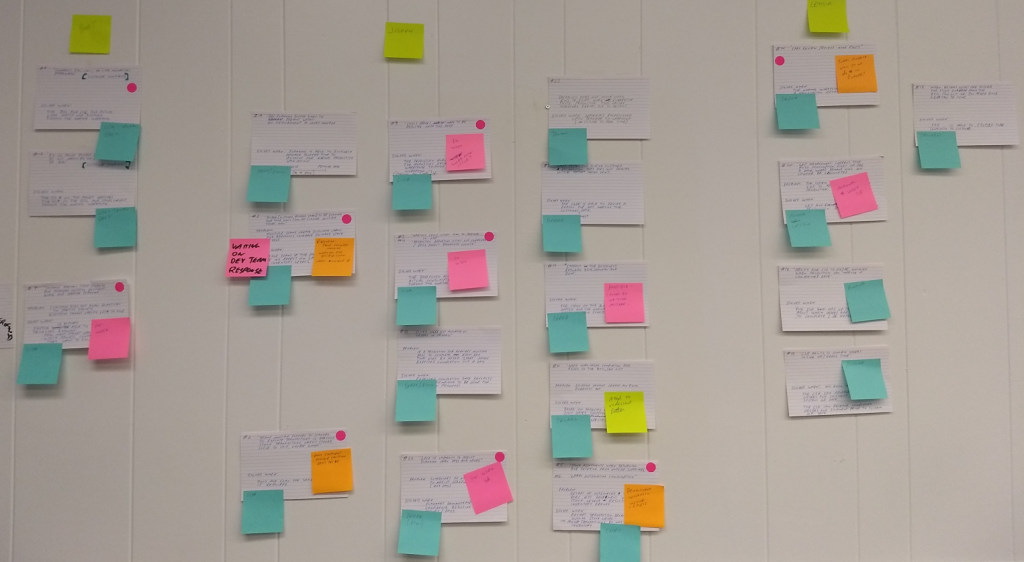

We established a vertical column on the wall for the work of each outside expert.

The stakeholder / managers now had to get together and agree on the priority order among themselves. The stakeholders controlled the priority. The cards were taped to the wall in priority order, top to bottom.

What we had now was stakeholder agreement on:

- What problems needed solutions.

- What “solved” means in clear terms from the perspective of the stakeholder.

- The priority sequence of work for each helping outside expert.

This meeting, by the way, wasn’t necessarily pretty. But they needed to work through the conflicts themselves. No outsider could do that except to impose something, which would reduce the ownership of the process.

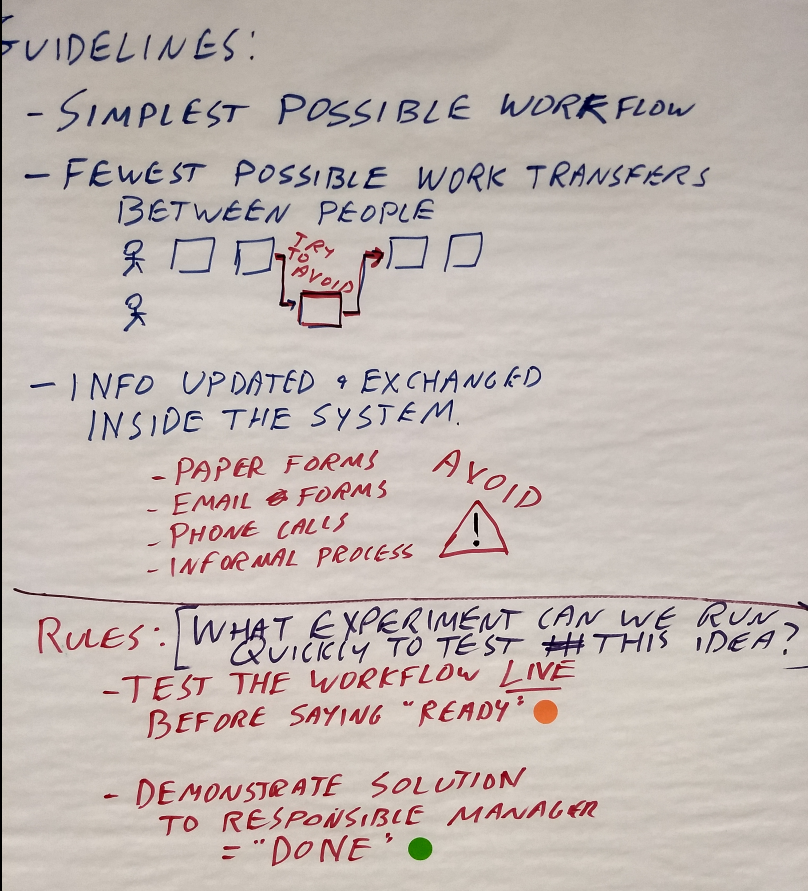

All of this effort was to make sure we were focused on workflow, not simply software features. All solutions had to be in the form of what someone had to do in order to advance the work.

Daily Management

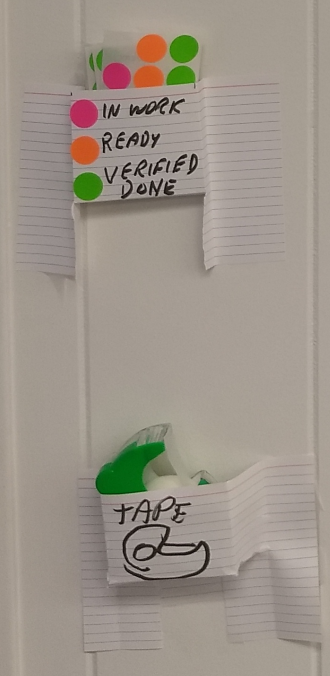

We used sticky dots to indicate the status of each card. The colors were based on nothing more than the box of stickers I could find at the local wally-world.

When the outside expert began work on a particular problem, they would put a pink dot on the card. This signaled to everyone that this problem was “in work.”

If they encountered any issues or delays, they would put a post-it on the card saying what question needed to be answered, or what was needed to resume work. This indicated “Stuck” status and what must be done to get it “Unstuck.”

They typically worked with the individual Team Members who had to use the system to do their work. Sometimes, though, they had to get answers from outside, or even facilitate modifications to the system.

When the outside expert believed the solution was Ready to demonstrate to the Stakeholder for buy-off, they put an orange dot on the card.

They also moved the card to another column on the wall under the stakeholder’s name. This established the work queue for the stakeholders. It was now their responsibility to initiate the next action. It was clear who was waiting for who.

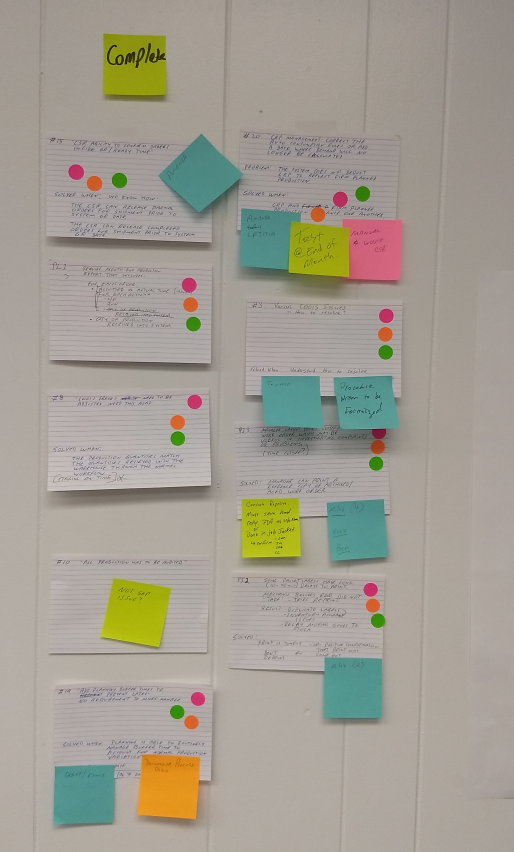

Once the stakeholder was satisfied with the solution, they (and only they) applied a green “Verified / Complete” dot, and the card was moved to the “Completed Items” section of the wall. That showed we were making progress.

Process Guidelines

We also established agreement around workflow guidelines, a set of loose standards to strive for in a solution.

Staying Aligned

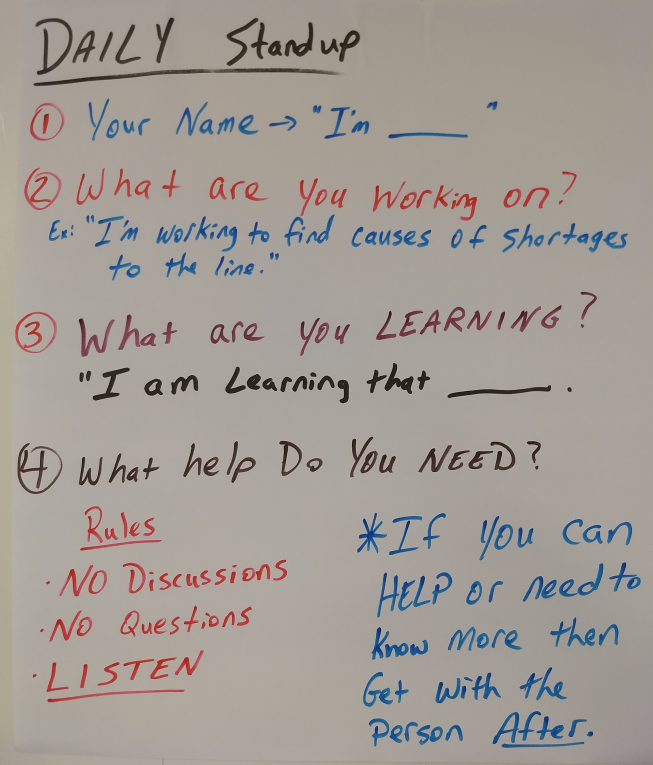

We established a daily standup every morning at 10:00.

The purpose was to align on status. It was NOT to solve problems. The meeting took 10 minutes or less, each person speaking for less than 60 seconds. This was the time to mention if you were blocked on making progress, or if you needed help.

To facilitate the structure we used a “talking stick” – something that was passed from person to person indicating it was their turn to talk, and that everyone else’s task was simply to listen. Question, discussions, possible solutions, etc. were, “I can help with that, let’s meet after” and the meeting was typically followed by quick 2-3 person huddles.

Transparency = Progress

By having everyone working toward a shared Truth that was displayed for all to see, there was no opportunity for speculation, wondering who was working on what, why progress was stuck.

Possible solutions were investigated, and results reported at the daily standup, AND on sticky notes on the cards.

Everyone know if the next step was their responsibility (because the card was on the wall under their name).

There were no action item reviews, no “I’ll have that done next week.” Every task was on a timeline of Today and Tomorrow.

At the same time, this process was a shock to the organizational culture which was pretty much the opposite of everything I just said.

Great example! Thank you for sharing.

So the management got hands-on experience, with a successful outcome. Did they manage (and did they what) to improve the org culture afterwards?

Tord –

Good question. There have been a lot of changes and turnover on the site since then, so I can’t speak for what happens today.