Imagine you are driving an automobile with a high-performance suspension. You are on a perfectly straight stretch of road, with smooth pavement. Get yourself up to, say, 65 miles per hour (100 km/h). Got it pointed down the middle of the road?

OK, close your eyes, let go of the steering wheel and wait. (Actually closing your eyes is optional.)

Can you predict what will happen, more likely sooner than later?

It doesn’t matter how “stable” your car is.

There are small, random things that are eventually going to cause your car to drift away from the centerline and off the road, into the ditch on one side, or over the cliff on the other. (Didn’t I mention those?)

I often see people set up a well performing process and treat it the same way – as though it will continue to work the same way forever, without any intervention.

But your process is going to encounter random chatter, and when it does, what typically happens?

In most cases, the team members can find a way to work around the issue, and likely continue to get things done, though they will have added a bit of friction, requiring a bit more effort, to do so. They will add a redundant check to make sure no mistake got made. They will add some inventory under the work bench, in case something runs out. They will carry the product over to the other machine because the one they are supposed to use isn’t working as it should be.

They will clean up the spilled coolant, catch the leaking oil.

They will head up-line to borrow a team member’s grease bucket.

They’ll tap out paint clogged or unthreaded holes, cut wires that are delivered too long to length, even drill new holes to mount the part that doesn’t fit.

In the office, they get one more signature, send an email to back-up the “unreliable” ERP messages, and make screen prints so they can enter the data into another system.

“Waste is often disguised as useful work.”

All of this easily goes unnoticed, and eventually (maybe) the process becomes cumbersome enough that someone decides to address it with an improvement activity. And the cycle starts again.

How do we stop the cycle?

The point of intervention is in the last paragraph… “All of this goes unnoticed.”

It isn’t a matter of standing and watching for problems. Sakichi Toyoda figured that out almost 100 years ago. It is about designing your process to detect anomalies in either execution (how it is done, how long it takes) or results immediately, signal, and trigger some kind of response.

Here are some fundamental questions to ask yourself:

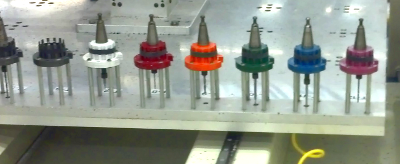

Before the process even begins, does the team member have everything he needs to succeed? How does he know? I’m talking about parts, information, tools, air pressure, assistance… whatever you know is needed to get the job done.

If the team member doesn’t have everything needed exactly what do you want him to do?

Is the team member carrying out the process in a way that gets the desired result? How does she know? Is there a sequence of steps that you know will give her the result you want? What alerts her if one of them is skipped?

If the team member, for whatever reason, isn’t able to carry out those steps in sequence, exactly what do you want her to do? Go find a grease bucket? Or let you know?

How long do you want to allow your team member to try to fix something or make it work before letting you know there is a problem? Related to this – how far behind can you allow him to get before he can’t catch up, even with help?

Once the team member has completed the process, how does he know the result is what was expected? If the team member doesn’t have a way to positively verify a good outcome, who does detect the problem, when, where and how? It might be your customer!

An Active Control System

Even if you have all of those checks in place, however, you still need to answer a few more questions starting with “Once the team member detects a problem, what do you what exactly do you want them to do?”

I alluded a little to this above, but let’s go a bit deeper.

On a production line, a typical way for a team member to signal a problem is with some kind of andon. This might, for example, take the form of a rope along the line that the team member can pull in order to trigger a signal of some kind.

But that is the easy part. Lots of factories have copied the mechanics of Toyota’s andon only to see them fall into disuse following a period of cynicism.

The hard part is what is supposed to happen next?

Now we are back to the original questions because the andon is nothing more than a trigger for another process.

Who is the designated first responder? (Remember, if it is everybody’s problem, it is nobody’s problem.) Does that person know who he is?

What is the standard for the response? What is the first responder supposed to do, and how long does she have to do it?

When we had takt times on the order of dozens of minutes, our standard for the first response making face-to-face contact with the team member who signaled was 30 seconds.

How much intervention can the first responder make before being required to escalate the problem to the next level?

As a minimum

As a minimum, the first responder’s primary goal is to restore the normal pattern of work. This might be as simple as pitching in and helping because something minor tripped up the team member’s timing.

This is active control – a system or process that detects something going outside the established parameters, and applying an adjustment to get it back. Active control requires a process to detect abnormalities, a trigger, and a response that restores things. It is no different than maintaining thickness in a rolling operation – the machine measures the output, and adjusts the pressure accordingly – or an autopilot that keeps an airplane on course.

Without some kind of active control system, your process will erode over time as the team members do the only things they can do in an effort to keep things moving: They can overproduce and build inventory to compensate, they can add extra process steps, they can add just about any of the things we call “waste.”

The only question is what do you want them to do?

These plants are capital intensive, and the main focus of the people is to keep the equipment running.

These plants are capital intensive, and the main focus of the people is to keep the equipment running.