The title of this post was a repeating theme from KataCon 3. It is also heavily emphasized in Mike Rother’s forthcoming book The Toyota Kata Practitioner’s Guide (Due for publication in October 2017).

What is the Threshold of Knowledge?

“The root cause of all problems is ignorance.”

– Steven Spear

September 1901, Dayton, Ohio: Wilbur was frustrated. The previous year, 1900, he, with his brother’s help1, had built and tested their first full-size glider. It was designed using the most up-to-date information about wing design available. His plan had been to “kite” the glider with him as a pilot. He wanted to test his roll-control mechanism, and build practice hours “flying” and maintaining control of an aircraft.

But things had not gone as he expected. The Wrights were the first ones to actually measure the lift and drag2 forces generated by their wings, and in 1900 they were seeing only about 1/3 of the lift predicted by the equations they were using.

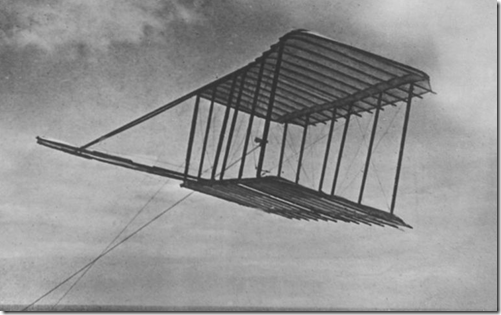

The picture below shows the 1900 glider being “kited.”. Notice the angle of the line and the steep angle of attack required to fly, even in a stiff 20 knot breeze. Although they could get some basic tests done, it was clear that this glider would not suit their purpose.

In 1901 they had returned with a new glider, essentially the same design only about 50% bigger. They predicted they would get enough lift to sustain flight with a human pilot. They did succeed in making glides and testing the principle of turning the aircraft by rolling the wing. But although it could lift more weight, the lift / drag ratio was no better.

What They Thought They Knew

Wilbur’s original assumptions are well summarized in a talk he gave later that month at the invitation of his mentor and coach, Octave Chanute.

Excerpted from the published transcript of Some Aeronautical Experiments presented by Wilbur Wright on Sept 18, 1901 to the Western Society of Engineers in Chicago (Please give Wilbur a pass for using the word “Men.” He is living in a different era):

The difficulties which obstruct the pathway to success in flying-machine construction are of three general classes:

- Those which relate to the construction of the sustaining wings;

- those which relate to the generation and application of the power required to drive the machine through the air;

- those relating to the balancing and steering of the machine after it is actually in flight.

Of these difficulties two are already to a certain extent solved. Men already know how to construct wings or aeroplanes which, when driven through the air at sufficient speed, will not only sustain the weight of the wings themselves, but also that of the engine and of the engineer as well. Men also know how to build engines and screws of sufficient lightness and power to drive these planes at sustaining speed. As long ago as 1884 a machine3 weighing 8,000 pounds demonstrated its power both to lift itself from the ground and to maintain a speed of from 30 to 40 miles per hour, but failed of success owing to the inability to balance and steer it properly. This inability to balance and steer still confronts students of the flying problem, although nearly eight years have passed. When this one feature has been worked out, the age of flying machines will have arrived, for all other difficulties are of minor importance.

What we have here is Wilbur’s high-level assessment of the current condition – what is known, and what is not known, about the problem of “powered, controlled flight.”

Summarized, he believed there were three problems to solve for powered, controlled flight:

- Building a wing that can lift the weight of the aircraft and a pilot.

- Building a propulsion system to move it through the air.

- Controlling the flight – going where you want to.

Based on their research, and the published experience of other experimenters, Wilbur had every reason to believe that problems (1) and (2) were solved, or easy to solve. He perceived that the gap was control and focused his attention there.

His first target condition had been to validate his concept of roll control based on “warping” (bending) the wings. In 1899 he built a kite and was able to roll, and thus turn, it at will.

At this point, he believed the current condition was that lift was understood, and that the basic concept of changing the direction by rolling the wing was valid. Thus, his next target condition was to scale his concept to full size and test it.

What Happened

Wilbur had predicted that their wing would perform with the calculated amount of lift.

When they first tested it at Kitty Hawk in 1900, it didn’t.

However, at this point, Wilbur was not willing to challenge what was “known” about flight.

Instead the 1901 glider was a larger version of the 1900 one with one major exception: It was built so they could reconfigure the airfoil easily.

Impatient, Wilbur insisted on just trying it. But, to quote from Harry Combs’ excellent history, Kill Devil Hill:

“The Wrights in their new design had also committed what to modern engineers would be an unforgivable sin. […] they made two wing design changes simultaneously and without test.4”

Without going into the details (get the book if you are interested) they did manage to get some glides, but were really no closer to understanding lift than they had been the previous year.

They had run past their threshold of knowledge and had assumed (with good reason) that they understood something that, in fact, they did not (nobody did).

They almost gave up.

Deliberate Learning

Being invited to speak in September actually gave Wilbur a chance to reflect, and renewed his spirits. That fall and winter, he and his brother conducted empirical wind tunnel experiments on 200 airfoil designs to learn what made a difference and what did not. In the process, as an “oh by the way,” they invented the “Wright Balance” which was the gold standard for measuring lift and drag in wind tunnel testing until electronics took over.

They went back to what was known, and experimented from there. They made no assumptions. Everything was tested so they could see for themselves and better understand.

The result of their experiments was the 1902 Wright Glider. You can see a full size replica in the ticketing area of the Charlotte, NC airport.

I’ll skip to the results:

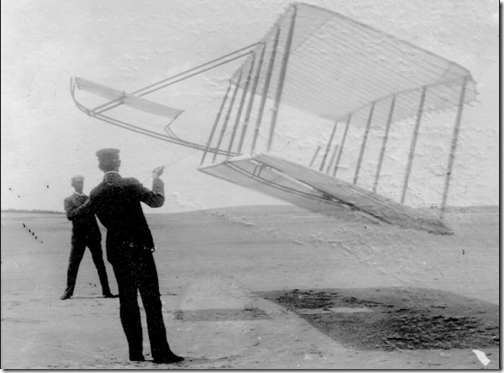

Notice that the line is now nearly vertical, and the wing pointed nearly straight forward rather than steeply tipped back.

What Do We Need to Learn?

Making process improvements is a process of research and development, just like Wilbur and Orville were going through. In 1901 they fell into the trap of “What do we need to do?” After they got back to Dayton, they recovered and asked “What do we need to learn?” “What do we not understand?”

The Coaching Kata

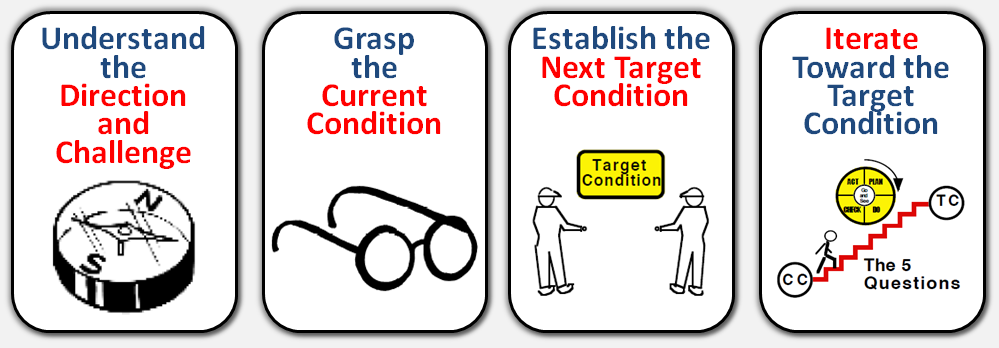

What I have come to understand is the main purpose of coaching is to help the learner (and the coach) find that boundary between what we know (and can confirm) and what we need to learn. Once that boundary is clear, then the next experiment is equally clear: What are we going to do in order to learn? Learning is the objective of any task, experiment, or action item, because they are all built on a prediction even if you don’t think they are.

By helping the learner make the learning task explicit, rather than implicit, the coach advances learning and understanding – not only for the learner, but for the entire organization.

Where is your threshold of knowledge? How do you know?

________________________________

1We refer to “the Wright Brothers” when talking about this team. It was Wilbur who, in 1899, became interested in flight. Through 1900 it was largely Wilbur with his brother helping him. After 1901, though, his letters and diary entries start referring to “we” rather than “I” as the project moved into being a full partnership with Orville.

2The Wright Brothers used the term “drift” to refer to what, today, we call “drag.”

3Wilbur is referring to a “flying machine” built by Hiram Maxim.

4I’m not so sure that this is regarded as an “unforgivable sin” in a lot of the engineering environments I have seen, though the outcomes are similar.