So many of us were wringing our hands a year ago. Our idealized vision of Toyota as the source of all perfection and example was tarnished and crumbling before our eyes. Prominent “names” in our field were talking about the need to go beyond Toyota. The vaunted TPS was clearly failing.

So many of us were wringing our hands a year ago. Our idealized vision of Toyota as the source of all perfection and example was tarnished and crumbling before our eyes. Prominent “names” in our field were talking about the need to go beyond Toyota. The vaunted TPS was clearly failing.

Or was it?

Like everyone else, I could only speculate based on a mix of the (mis) information emerging from regular press reports, the opinions of some insiders, and the insights I could glean from contacts with direct access into the company.

When McGraw-Hill offered an early copy of the book for review, I eagerly accepted because I, too, wanted to know the whole story. (<— smooth, seamless disclosure for the benefit of the FTC)

What really happened?

That is the question that Jeff Liker (with Timothy Ogden) set out to answer in the book Toyota Under Fire.

Losing Money

When I hear the term “Toyota under fire” I think of the “sudden uncontrolled acceleration” debacle from late 2009 through the spring and summer of 2010.

Perhaps that is because I didn’t consider that reporting three quarters of losses was the kind of adversity I would consider “under fire.” At least not for Toyota.

In retrospect, I probably glossed over that period because I felt I could predict Toyota’s response to the great recession and the economic problems it caused them – they would double down on what they have always done, and strive to do it even better than they had in the past.

They would first work to get the problem contained – and return to profitability without compromising their core values.

Then they would work to eliminate the root cause(s) of the problem by reducing their break even point.

The result would be the emergence of an even more formidable competitor that is capable of weathering an identical recession without incurring these losses.

And, according to Liker and Ogden, that is exactly what happened.

In the first half of the book, they tell the story of how Toyota responded to the recession in a rich detail that captures how this amazing corporate culture functions when it is under financial pressure it has not experienced since 1950.

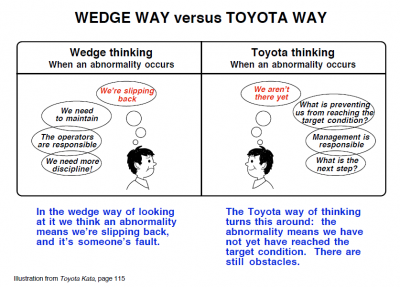

What we see is the entire company mobilizing and carrying out its kata pretty much as described by Mike Rother in his book.

But there is also more. We see that this was only possible because the company had worked hard in the good times to be prepared for this kind of adversity, even as it was unthinkable. This enabled Toyota to do things that only Toyota could do.

No matter what other companies may say about their values around team members and suppliers, there are few that could (or would) continue to make payroll, support key suppliers, and continue to invest in R&D while reporting losses and facing a 30% drop in their top line, even if they wanted to.

And we see another side of the story – how an incredibly ignorant, uninformed and uncurious press force-fit the things they saw into their own management paradigms – turning a show of strength in the face of adversity into a negative story. It turns out this is a precursor for what was to follow.

Losing Faith

In August 2009, just as the financial crisis was coming under control, a tragedy set a series of events into motion that would test the company to its very core.

…Mark Saylor and his wife, daughter and brother-in-law were killed when their Lexus, on loan from a dealer who was servicing the family’s own vehicle, careened out of control at more than 100 mph, collided with another vehicle, and crashed into a ravine, setting the car ablaze.

Liker and Ogden offer a comprehensive account of the events that unfolded over the next year while this story spun out of control as the press, politicians, attorneys all fed on – and added to – the public’s fears about the safety of their automobiles.

The story is both fascinating and frustrating as Toyota’s technically oriented culture is focused on facts and data while it is confounded and overwhelmed by a political and litigation culture that focuses on sensationalizing rumors and innuendo.

Toyota learns a hard lesson – that reputation has less to do with the truth than about perception, and decades of work can be destroyed in weeks in the political-legal-press feeding frenzy.

In the end, though, the Toyota Way emerges. Just as they did in the recession, they accept responsibility for the things that affect them, regain focus on their customer’s needs – technical as well as emotional – and double down on what Toyota does best. This time, though, they learn to do that in a different context – the global / cultural one.

A great story in the classic mold of the protagonist emerging stronger from adversity while confronting his personal shortcomings.

Overall

I strongly recommend this book for anyone who wants to be able to articulate the story of how Toyota persevered through the most trying time in their history since they emerged as a global company. This was a transformative time for the company, possibly as significant as the losses and strike in the late 1940’s that set the path for the future.

That being said, there are two areas where I think Toyota Under Fire could have done better conveying this story.

The first is context. And context begins with background.

In the decades prior to all of this unfolding, Toyota had done little (in my opinion) to alter the public’s view of them as a “foreign” company even though they directly employed tens of thousands of people in the U.S. and sourced many millions of dollars of parts from U.S. companies. I believe they failed to put a human face on the American side of the company. They allowed the product to speak for them. In effect, they allowed their competitors to control a large part of Toyota’s cultural positioning.

Next is the aspect of technology. Liker and Ogden address the gap between engineering reliability of the electronic controls and the public’s emotional confidence in them.

Next is the aspect of technology. Liker and Ogden address the gap between engineering reliability of the electronic controls and the public’s emotional confidence in them.

However I am not sure they convey the cultural gap between that emotional confidence (or lack of it) in the USA vs. what would be felt in Japan or even Europe. Simply put, Americans are less trusting of technology in their cars. I am not certain the engineers in Japan fully grasped this gap. If they did, I am not certain they didn’t dismiss it.

With all of that as background, while the Saylor’s accident would have been tragic at any time, late August 2009 could not have been a worse moment for Toyota.

The accident was a scant two months after General Motors’ controlled immolation into government-owned bankruptcy, and the company was still breaking up. Chrysler was sold off to Fiat. Ford’s stock was selling for under $5.

And the day before the Saylor accident, Toyota had announced that the NUMMI joint venture was being closed after GM had pulled out.

With Toyota relatively healthy (compared to everyone else), still perceived as a “foreign” company, and seen by many as “responsible” for the demise of GM, they were operating in a public and political atmosphere that was fuel and oxygen rich. The Saylor accident was a spark.

Had Toyota grasped how precarious their political and cultural standing was, they might have acted much more aggressively and much sooner when this story started to unfold.

The fall of 2009 and spring of 2010 was slow for domestic U.S. news, so there was nothing to push the Toyota story out of the news cycle.

While Liker and Ogden correctly and accurately relate how Toyota managed to finally “get ahead of the story,” the precipitous drop in negative press reports about Toyota occurs in August 2010 – as the drama of the trapped miners in Chile begins to unfold.

I mention this context because it is not only important for the reader, but equally important for Toyota. They learned a hard lesson about the U.S. news cycle, especially how a story can get legs under it. This had to be tough for a company used to dealing in a world of verifiable facts and data.

To a company who values, above all, being in control of their own destiny, they had allowed much of the background to be written by others.

This story was as much about Toyota’s total lack of an emotional connection into the overall U.S. culture as it was about their cars and engineering. And while Liker and Ogden talk extensively about Toyota’s aggressive countermeasures to establish better connections to customer’s perceptions, I would like to have read about how Toyota addressed (or didn’t) this cultural positioning as well.

The only other quibble I have is I believe the book could have been a little more tightly edited. I am giving this a pass, though, because the final technical report from NASA came out in March 2011, and this book landed on my porch a scant couple of weeks later – the ink was still wet. So from that standpoint, I recognize the last minute frenzy of writing and editing that had to be done to include the latest relevant information.

In the end – buy the book but recognize it is still a bit insular – much as Toyota can be. That is perhaps something they still need to address.

Breaking News

Two stories of interest as I am writing this.

(April 1) After deliberating for approximately 45 minutes, a jury reached a defense verdict in favor of Toyota Motor Sales, U.S.A., Inc. in an alleged unintended acceleration case brought by Dr. Amir Sitafalwalla, who claimed that an unsecured driver’s side floor mat was the primary cause of the crash of his Scion vehicle in August 2005.

During the course of the week-long trial, Dr. Sitafalwalla’s primary expert, Dr. Anthony Storace, withdrew his assertion that the Electronic Throttle Control System in the Scion could also have been a cause of the accident based on his acknowledgment that he had no basis to support that claim.

Of note is that the news reporting of this story is buried.

This story, however, was on the news tonight (April 4):

By BRUCE SCHREINER, Associated Press – Mon Apr 4, 4:56 pm ET

LOUISVILLE, Ky. – Toyota Motor Corp. said Monday that it’s inevitable that the company will be forced to temporarily shut down all of its North American factories because of parts shortages due to the earthquake that hit Japan.

The temporary shutdowns are likely to take place later this month, affecting 25,000 workers, but no layoffs are expected, spokesman Mike Goss said. Just how long the shutdowns last or whether all 13 of Toyota’s factories will be affected at the same is unknown and depends on when parts production can restart in Japan, he said.

So far the North American plants have been using parts in their inventory or relying on those that were shipped before the earthquake, Goss noted. But those supplies are running low.

“We’re going to get to a point this month where that gap in the pipeline starts to show up. So we’ll have to suspend production for a while,” he said.

While interesting, this story buries the lead into the middle of the second paragraph: “… affecting 25,000 workers, but no layoffs are expected.”

This statement is ambiguous, but if it means “we are going to keep paying everyone and working on improving the work while the plant is shut down” that is the story here. Otherwise, this sounds like a routine shutdown-and-furlough-the-workers story.

What makes it more interesting is that Toyota’s press release site refutes the story altogether:

NEW YORK, NY (April 4, 2011; Posted at 3:15 PM EDT) Contrary to recent headlines, nothing has changed from our update from March 23rd regarding our North American operations.

We continue to assess our supply base in Japan following the earthquake/tsunami. We have communicated to team members, associates and dealers here that some production interruptions in North America are likely. It’s too early to predict location or duration.

Currently, the greatest majority of parts for our North America-built vehicles come from approximately 500 suppliers in North America. Also, we continue to receive parts from Japan that were already in the pipeline, limiting the immediate impact. We will continue to work closely with suppliers in North America and Japan to minimize any disruptions to Toyota’s overall North American operations.

The reason I bring up this little chain of news stories is that it reinforces my notion that Toyota is still playing “business as usual” in how they manage the news cycle. In this case, no harm, but my questions for them are:

- What is your target condition for public perception of these stories?

- What is the current public perception?

- If there is a gap, what is keeping it from being closed?

- What is your plan to address that issue?

- When can we see what you have learned from the first step?

because every process is subject to kaizen.